|

| |

Powertrain which moves the world ! We are convinced that the biggest challenge facing us is to develop and produce eco-friendly products. It goes without saying that we will put into the market top quality products at the optimum price which will satisfy our customers. Our efforts do not stop there. We will develop “the only one in the world” products by improving our environment-oriented technology, implement thorough cost cutting at every single production plant, and execute energy-saving activities. By doing so, we will meet not only the auto industry needs but also various other social needs. |

|

|

|

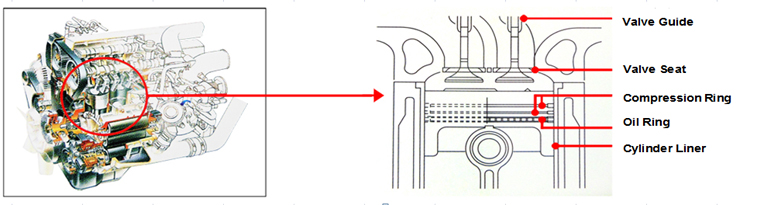

TPR\'s products |  |

|

| |

Powertrain Maker |

|

|

| |

Piston Rings

Cylinder Liners

Valve seats

Valve guides |

|

|

|

| |

FA and Electrical parts and Plastic parts |

|

|

| |

Slide guide for the rubber seal

O-ring

Aluminum foil heater

Plastic parts:Plastic extruding

|

|

|

|

| |

TPRV Environmental Technology |

|

|

| |

The automobile society and next-generation engines face a number of challenges, particularly the need for improved fuel efficiency to more effictivity use limited resources and restrictions on exhaust emissions to halt global warning. TPRV is contributing to development of engines that are gentle on the environment by leveraging its expertise and original technologies.

|

|

|

|

|

|

|  | Main Products |  | Piston Rings

Piston Rings that control lubrication oil are an important functional component requiring high precision and durability since they are used in parts moving at great speed.

Cylinder Liners

With the recent demands for fuel efficiency, higher performance, and lighter weight engine, there is a growing trend for improving cooling performance, reducing clearance between cylinder, and using aluminum blocks, Consequently, TPRV's is striving to improve adherence to the aluminum block by applying centrifugal casting method to make lines thinner, and thereby achive lower costs.

Valve seats

For materials used in production of sintered alloy valve seats, TPR breaks down particles using our proprietary special alloy powder. Featuring an excellent balance of heat resistance, wear-resistance, and compatibility with valves indispensable for valve seats, TPRV provides sintered alloy products that are compatible with all engines, including diesel, gasoline, and gas for either two or four wheel vehicles.

Valve guides

Valve guides support the stem of inlet and exhaust valves, keeps valve stabilization and helps to conduct the heat of valve to the cylinder head, durability and high precision are needed. Our Sintered material valve guides are excellent in wear resistance, heat resistance and mechanical properties, adopted with number of gasoline engines and diesel engines.

|  |

|

|

|

|

|